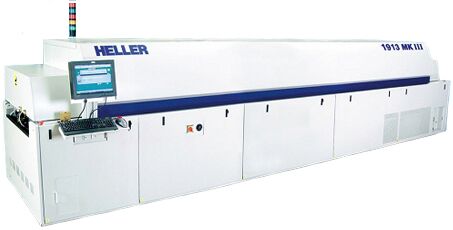

Mark III - 1913

PRODUCT DESCRIPTION

MK III Series

Best value SMT Reflow Oven in the market. Designed for Low Cost of Ownership.

1913 The ultimate high volume Surface Mount Technology production solution with belt speeds up to 1.4m/min to accommodate the fastest pick-and-place systems delivering the highest levels of repeatability with the lowest delta Ts. With a high-capacity, 26-inch wide heater module, the 1900 Mark III Series offers unmatched flexibility in board handling. The oven may be fitted with an adjustable single-rail edge hold conveyor/mesh belt combo, to carry even the largest boards or multi-board panels (up to 20 inches wide) through the oven.

FEATURES

- The most efficient heat transfer from extra high volume, high-velocity, heating modules, producing heater module response of less than one second to temperature changes of less than 0.1ºC, thereby maintaining profile integrity for heavy board loads.

- Wide process window for "universal profiling" - allows many different boards to be run on a single temperature profile.

- Advanced 5 thermocouple PCB profiling and process parameter logging capability with the capacity to store up to 500 temperature recipes and 500 profile graphs.

SPECIFICATIONS

- Pure forced convection heating

- Advanced Windows operating system with:

- Data logging

- Alarm logging

- 3 T/C profiling with KIC Auto-Focus Power™ software

- ECD CPK software

- Mesh belt

- Air atmosphere processing

- Lead-Free processing

- Available Features:

- 400° and 450° available

- Edge hold conveyor

- Nitrogen option with 100 PPM @ < 900 SCFH

- GEN 5 waterless flex separation system

- Nitrogen retrofittable capability

- Nitrogen Retrofit option

- RMATS-Remote Monitoring and Technical Support option

- ETL/CE certification

- Dual edge hold conveyor

- Water cooling

- GEM/SECs interface

- Industry 4.0 communication